Our history began in 1889 - over 135 years of experience in compaction

Since our foundation in 1889, Mehrer has been one of the oldest compressor manufacturers in the world. In the following, we present the most important milestones of our traditional company.

Josef Mehrer and his brother-in-law founded the Roller & Mehrer workshop in Balingen. They manufactured lathes and sewing machines. After 25 years, the founders parted company.

Josef Mehrer opened his own workshop at Neue Straße 3 in Balingen and specialised in the sale and repair of air pumps for the beer industry and bicycles.

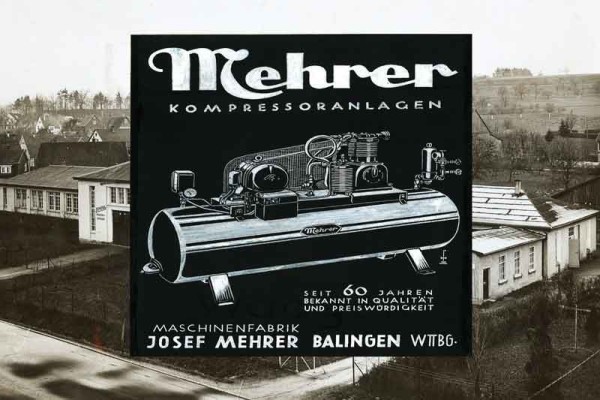

After the death of Josef Mehrer, his sons Karl and Bernhard continued to run the business. However, the First World War brought with it considerable challenges. During this time, the company was renamed ‘JOMEBA’, an abbreviation for ‘Josef Mehrer Balingen’.

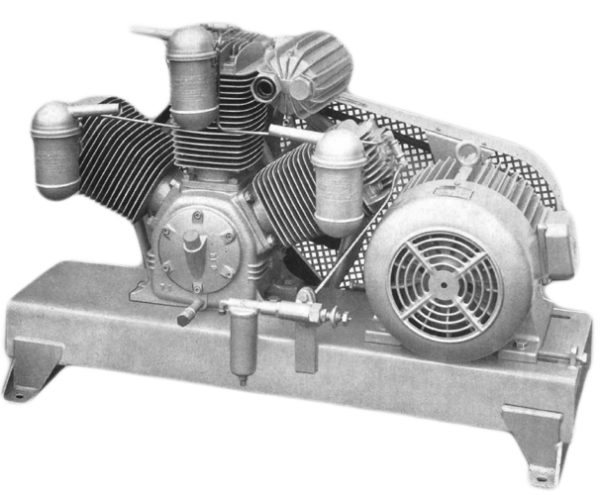

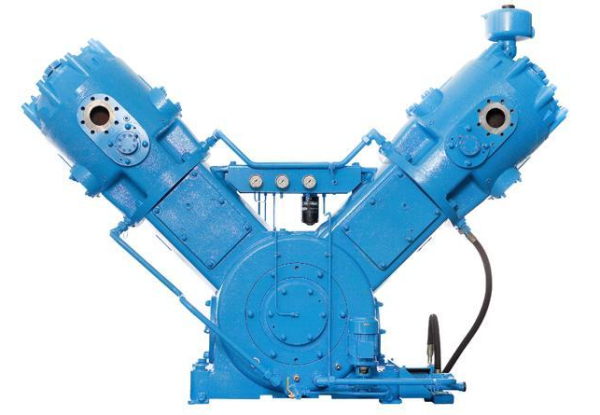

Manufacture of oil-lubricated air compressors for industrial applications

Following the acquisition of Maschinenfabrik Link, the company relocated to its current site at Rosenfelder Straße 35 in Balingen.

With Bernhard II, the third generation joined the family business and continued the tradition of the company.

The name ‘JOMEBA’ was changed to ‘Mehrer’.

Development of the first oil-free multi-compressor

With the development of dry-runners for breweries, the business was expanded and the operation was extended.

New production facilities and an office building were inaugurated at the existing site.

With Bernhard III as well as Klaus and Rudolf, the fourth generation joined the company.

The business expanded with compressors for CO2 recovery, and the internationalisation of the company began.

Development and market launch of the TRx 700 and TVx 900 series for process gas applications

Jörg-Peter Mehrer takes over the company and continues the family tradition in the fifth generation.

Development and market launch of the TRx 200 and TRx 300 series for process gas applications

Expansion of the product portfolio to include diaphragm compressors

Development and market launch of the TRZ 1000, which is primarily used for oil-free CO2 compression

Development of the TRx 400 high-pressure compressor for final pressures up to 200 bar(a).

Development of high-pressure booster TRx 700

Standardisation of the product range & first hydrogen filling station in the Zollernalb district

Development into a system provider