Our purity principle: Absolutely oil-free

Our oil-free compressors have been indispensable in the food and beverage industry for many years. They offer a reliable, clean and efficient solution wherever maximum purity is required - especially in CO2-compression.

Your benefit

Our CO2-compressors work absolutely oil-free and have proven themselves in practice. They are the perfect choice when pure carbon dioxide is required - without any complicated cleaning processes. They offer maximum process safety and efficiency.

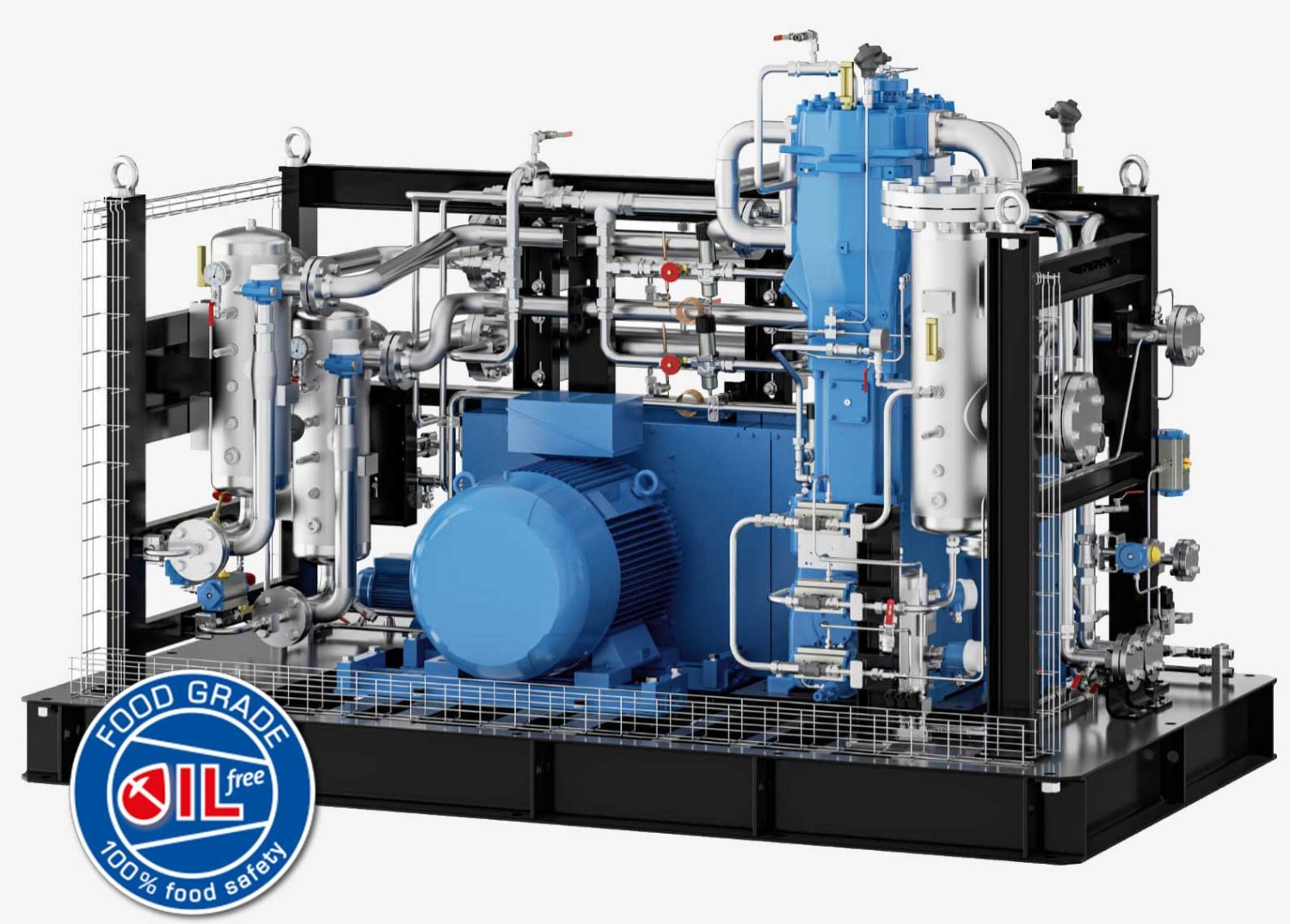

Our CO2-compressors - oil-free and with many other advantages

1 | Gas pipework - Made of stainless steel for high durability

2 | Separator - With automatic condensate drain made of stainless steel

3 | Heat exchanger - Made of stainless steel tube bundles for efficient cooling

4 | Drive motor - Prepared for frequency inverter operation

5 | Base frame - For vibration-isolated or fixed mounting

6 | Valve lift-off - Diaphragm-controlled for volume flow control

Our Food-Line

With our Food-Line compressor systems, we ensure that your gases remain absolutely pure and that no contamination is caused by our compressors. Our Food-Line fulfils the following conformities:

- Suitable for food contact

- Regulation (EU) 10/2011

- Regulation (EU) 1935/2004

- Requirements of the US FDA

- BfR Recommendations XXI

- Certification by the NSF (National Sanitation Foundation, USA)

Optional modules for your Food-Line product range

- Secondary cooling circuit

- Gas quality test

- Control unit

- Volume flow control

- Dry ice generation

- Insulated cooling water circuit

- Filter monitoring

- Gas process control

Put together the optimum compressor for your process from our modular product portfolio. By combining basic types with suitable system components, you receive complete compressor units and systems from a single source.