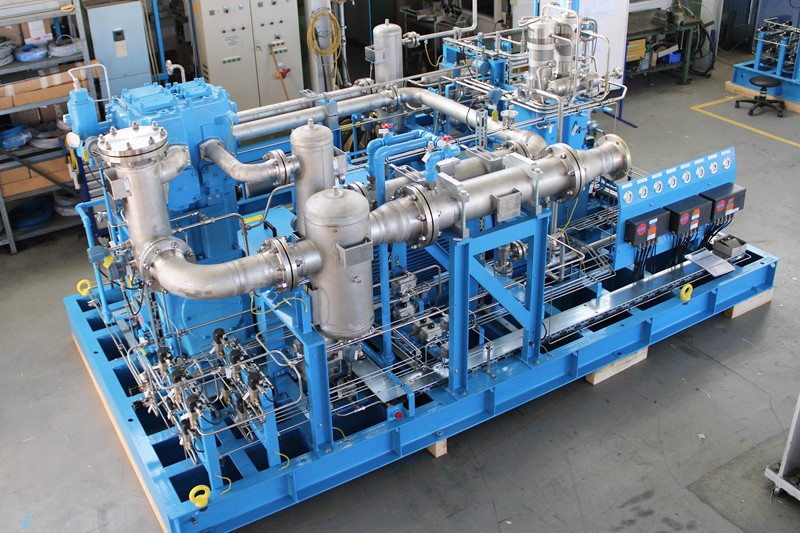

Hydrogen compressors for the energy transition

Application | Core component between electrolysis and hydrogen refuelling station

Country | USA

For use at hydrogen refuelling stations, the hydrogen obtained from electrolysis must first be compressed and stored in tanks. With an intake pressure of 1 bara, the hydrogen is compressed to 201 bara using a combination of the oil-free TRZ 1000 and TRZ 700 compressors. Both compressors are directly driven by a main motor and operate in two stages per compressor unit.

A special feature of the system is the automatic condensate discharge: as the hydrogen from the electrolysis is saturated with water vapour, condensate is separated after each compressor stage to prevent the accumulation of water in the compressor. The system is delivered to the USA and fulfils the requirements of ASME B31.12 ‘Hydrogen Piping and Pipelines’.

| Series | TRZ 1000 / TRZ 700 |

| Description | 4-stage, double-acting |

| Suction pressure | 1 bar(a) |

| Final pressure | 201 bar(a) |

| Volume flow | 535 Nm3/h |

| Gas state | 100% saturated with water vapour |

| Compressor cooling | Water-cooled |